With so many technological innovations hitting the automobile market and making big promises, it can be pretty hard to find the exact ones that improve the driving experience. Thermal imaging technology is a good choice as the night vision capabilities it brings to the automotive industry vastly improve safety during night driving. Except for the night vision feed, thermal imaging camera measures the temperature of various parts of cars and quickly visualizes thermal defects through images. Not surprisingly, thermal camera figures prominently in the automotive R&D, repair and maintenance, contributing to its safety assessment and keeping away from accidents caused by vehicle failures. Let’s get started to learn how it is applied.

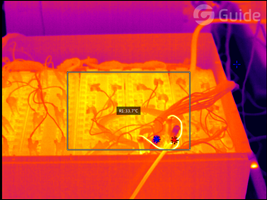

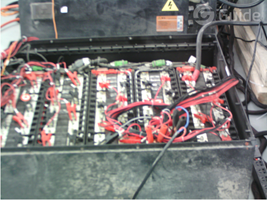

1. Lithium-ion Battery Charge-Discharge Test

Lithium-ion batteries power alternative fuel vehicles significantly, but they are extremely sensitive to high temperatures and inherently flammable. The temperature detection of these batteries becomes the focus of manufacturers, especially for battery charge/discharge testing.

Lithium-ion battery thermal inspection during a charge/discharge test

During the charging and discharging test, a Guide thermal camera can quickly and accurately present the temperature distribution of the lithium-ion battery from a long distance, monitor the abnormal temperature of the battery pack in real time, and generate the temperature trend to assist the analysis of battery conditions.

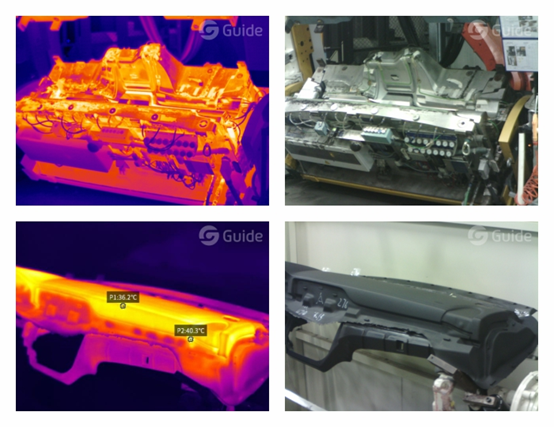

2. Motor Testing and Troubleshooting

Motor is a core component of a car, and generally needs to be evaluated through noise and vibration tests. However, these tests may not reveal some defects, such as tiny cracks and subtle structural design differences. Moreover, it is even more difficult to find where the defects are. As a result, increased fuel consumption and aggravatedly worn parts will reduce the service life of the motor. To solve these obstacles, an appropriate Guide thermal camera can be taken into account. It visualizes the subtle temperature difference due to structural failures and locates them accurately.

Motor thermal inspection by Guide PC210

Besides, measuring the temperature of the exhaust pipe and the cooling water pipe is very instrumental in understanding how well a motor works. When a thermal camera shows the temperature of the exhaust pipe is too high, it should be incomplete combustion, which also reflects the working condition of the motor. Overheated cooling water pipes can deform, crack or swell the motor. On the contrary, low temperature will make the oil flow slowly, resulting in severely damaged parts and increased mechanical loss of the motor.

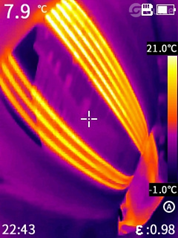

3. Testing the Lines on the Rear Windshield

Heating the rear windshield has been important to defrost the back window of a car in autumn, winter and rainy seasons. Guide thermal imagers create detailed thermal images of the heated grid lines to gain valuable temperature data and provide the temperature trend analysis. By using it, the unevenly heated lines and abnormal resistance can be noticed timely to avoid the damage to the glass.

Lines inspection by a Guide thermal camera

Heating the rear windshield has been important to defrost the back window of a car in autumn, winter and rainy seasons. Guide thermal imagers create detailed thermal images of the heated grid lines to gain valuable temperature data and provide the temperature trend analysis. By using it, the unevenly heated lines and abnormal resistance can be noticed timely to avoid the damage to the glass.

4. Inspection of Brake Pads

Brake pads are a vital component of every disc brake braking system used in automotive. Measurement of the temperature of brake pads can give a good understanding of its braking performance and wear resistance, which plays a significant role in the evaluation of brake pad materials.

Brake pads inspection by Guide D series thermal camera

5. Heated Seat Inspection

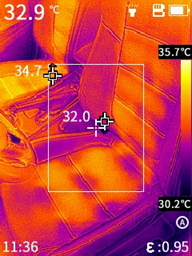

Inside the seat are heating coils that acts as resistors. When electricity flows through the coils, they resist the electricity and produce heat. This rises through the seat cushion and warms the occupant. With the help of the Guide intelligent infrared thermal imager, the heat conduction of the seat can be presented, the distribution of the heating wires can be "see-through", and the heating areas can be clearly viewed from the thermal images to evaluate the heating design.

Heated seat inspection by Guide PC210

6. Air Leakage Detection for Car Body

The quality of the air conditioning system is very important to the driving experience in summer and winter, and the air tightness of the car body directly affects the operation of the air conditioner. Utilizing a Guide PC series thermal camera to check the hot or cold spots from the joint images of various parts of the body after the air conditioner has been running for a while. If small temperature difference is found, there may be the air permeability problems.

Car dashboard inspection by Guide thermal camera

In a summary, infrared thermal imaging has become an indispensable detection technology in the automotive field. It can also respond to LED lamp shade, suspension, wheel casting, bearing system, electrical equipment, body comfort, etc. Infrared detection and diagnosis effectively guarantee the automobile R&D and production.

.svg)