When it involves designing and producing the delicate printed circuit boards (PCB), it is quite difficult to discover some design imperfections or manufacturing defects using traditional optical inspection methods because traditional optical inspection requires accumulated experience and time. However, the thermal imaging camera provides another way for inspecting PCBs that is reliable, simple and fast.

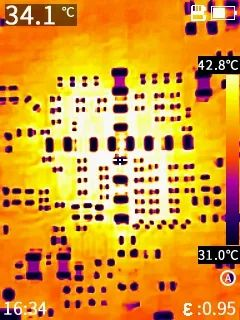

When a PCB is supplied with voltage, electric current flows through the board and the board starts to heat up. The thermal fields of the PCB can then be determined and visualized by thermal imaging via a thermal camera, especially the significant heating of certain components. This can be caused by a range of defects, which include electric short circuits, open circuit or poor contact.

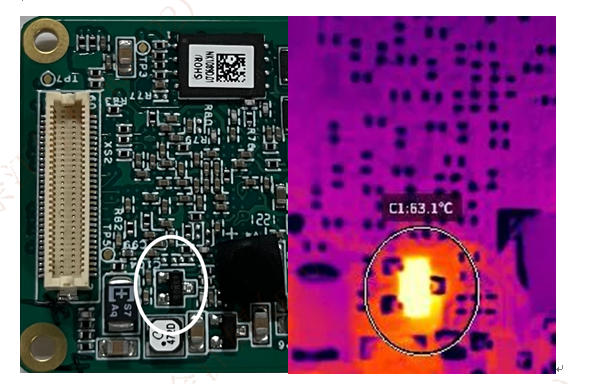

More specifically, thermography can be used to visualize the excessive heating of components with short circuits. A short circuit leads to the generation of an excess of voltage streaming and causes an excessive current to flow through. As a result, the temperature of the overheating components is higher on the thermal images. Similarly, an open circuit or poor contact exists when current cannot flow through the components and the temperature is lower, which is obviously visualized by thermal images.

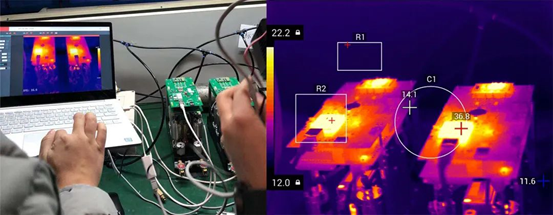

Thermal imaging can enhance the PCB design process, assist the simultaneous inspection of mounted PCBs and facilitate the immediate discovery of a wide range of issues after PCBs are mounted. With a thermal camera, the overall allocation of generated heat through the components on the PCB can be ascertained and the allocation of coolers and the layout design can be modified.

Guide Sensmart has released the PC230 thermal camera recently for the PCB inspection. With a recommended macro lens, this tool can be used to measure the temperature of micro electronic components like 0402 resistor and capacitor.

.svg)

_fuben.jpg)