Oilfield activities are normally conducted in vast and harsh environments, so protecting valuable assets is a key and ongoing challenge. Heavy temperature variations from scorching heat to cold, combined with adverse weather conditions and remote locations, render traditional monitoring methods futile. Infrared thermal cameras, a technological breakthrough, have become the ultimate all-weather protector of oilfield assets. This piece will take a closer look at how these infrared thermal cameras are transforming the operations of the oilfield, ensuring assets can operate uninterruptedly and efficiently in any environmental conditions.

Harsh Environment of Oilfield Operations

Oilfields are usually located in far-flung and very hostile climates. Throughout the daytime, the sun blazes in deserts at more than 50°C, and during nighttime, the temperature becomes near freezing point. In polar or high-altitude areas, spells of below-zero temperatures also pose many challenges. Frequent sandstorms, rains and snowstorms are common, in addition. Such harsh conditions not only endanger the integrity of oilfield equipment, but also make it challenging to identify problems such as pipeline inefficiency, equipment wear and abnormal operating modes in a timely manner. Traditional monitoring tools equipped with basic sensors are difficult to provide complete and real-time data, rendering assets exposed to the risk of potential damage and performance degradation.

How Infrared Thermal Cameras Work

Infrared thermal cameras operate on the straightforward principle of sensing infrared radiation from all objects whose temperature is greater than absolute zero. They differ from visible light cameras in the sense that they are able to "see" patterns of heat and process them into detailed thermal images that vividly show temperature differences. Each pixel in these images corresponds to a specific temperature value, allowing operators to precisely identify hot spots, cold spots, and irregular temperature distributions. Unaffected by lighting conditions, these infrared thermal cameras perform optimally in the dark of night, dense fog, or dusty environments. Equipped with advanced features such as high-resolution imaging, digital zoom, and long-range detection, modern infrared thermal cameras are able to monitor large areas accurately and reliably.

All-weather Adaptability: a Game-changer for Oilfield Operations

The excellent all-weather versatility of thermal imaging cameras has brought a great leap in the area of oilfield operation.

They are stable under intense heat and will not be undermined by overheating, allowing constant monitoring of critical equipment to detect signs of overheating or inefficiency early enough.

In the case of heavy rain, snow or any other unfavourable climatic conditions, their rugged wind-and-rain-proof enclosure protects interior components and ensures uninterrupted operation.

Even under low-visibility environments such as sandstorms or fog, these thermal-imaging cameras can penetrate obstructions and provide useful and clear thermal information.

Their reliability renders them suitable for all-weather year-round monitoring, enabling oilfield operators to manage assets actively irrespective of ambient environmental stress.

Optimizing Oilfield Asset Performance

Thermal imaging cameras are very critical in enhancing the life and performance of oilfield assets through numerous applications.

Precise Energy Management

Energy consumption is a major cost factor in oilfield operations. Thermal imaging cameras can accurately detect heat loss from pipelines, tanks and processing units. For example, by identifying areas where pipe insulation has failed, operators can address the problem promptly, reducing unnecessary heat loss and energy waste. This not only reduces operating costs, but also meets sustainable development goals by reducing the impact of energy inefficiency on the environment. In addition, analyzing the thermal patterns of energy-consuming equipment such as motors and compressors can help optimize their use, ensuring that the equipment operates at maximum efficiency and consumes energy more effectively.

Predictive Equipment Maintenance

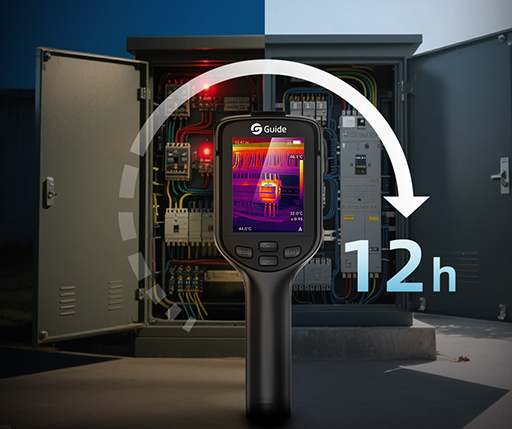

By continuous monitoring of temperature in equipment of oilfields, handheld thermal cameras make predictive maintenance possible. Gradual temperature increase might be an indication of an upcoming mechanical malfunction in equipment such as pumps and generators, motors, such as bearing wear, misalignment or electrical malfunction. By early identification of these abnormalities, maintenance teams are able to schedule the repairs at an optimal time and avoid costly production shutdowns due to unexpected failures. This active maintenance approach optimizes equipment life, but also reduces total maintenance costs due to emergency repairs and premature replacements.

Environmental Monitoring and Compliance

Operations in the oilfield are controlled by stringent environmental legislation. Handheld thermal cameras assist in monitoring the environment and assist in detecting leaks in pipelines, process plants or storage tanks early enough. Thermal changes are capable of detecting minor leaks so that they can be plugged before any potential pollution of the environment. In addition, these handheld thermal cameras can monitor the thermal impact of oilfield activity on the environment to authenticate compliance with environmental protection codes. By strictly monitoring environmental factors, operators of oilfields can avoid heavy fines and loss of reputation while carrying out their ecological responsibilities.

Conclusion

Infrared thermal cameras have proven to be a useful and indispensable tool in the oilfield industry, firmly guarding oilfield equipment and structures under any climatic condition. They can operate efficiently under extreme conditions and provide advantages in terms of accurate detection of performance-affecting issues that have revolutionized the maintenance and optimization of oilfields. Guide Sensmart is a manufacturer of infrared thermal cameras and would be honored to have your consultation.

.svg)

.svg)