In the current era of technological advancement for sensing and industrial automation, An infrared camera for thermal imaging has become an essential tool in almost every industry - from electrical maintenance and building inspection, to scientific research and defense. The ability to visualize temperature changes in real-time allows engineers, technicians, and researchers to make decisions faster and more accurately. In general, not all thermal imaging cameras are the same. The high-resolution thermal imaging camera produces sharper, more accurate images. Additionally, the high-resolution camera offers informative and data-rich thermal profiles that convey more subtle temperature discrepancies.

The article will explain what makes a high-resolution infrared thermal camera imaging system unique, what specifications truly matter, and how the correct camera selection can translate into measurable performance and efficiency in professional scenarios.

Understanding infrared thermal imaging

An infrared camera for thermal imaging detects infrared radiation, a form of electromagnetic energy that is emitted from any object at a temperature other than absolute zero. Unlike visible light cameras, infrared cameras visualize temperature differences rather than color or brightness. The resulting thermogram converts heat signatures into images that can be analyzed for diagnostics, surveillance, or research.

In an industrial setting, this technology can show overheated electrical connections, monitor mechanical wear, or locate insulation failures. Scientific and military applications again allow for the detection of thermal anomalies and motion in total darkness.

Why Resolution Matters in Thermal Imaging

Of all the specifications for any high-resolution thermal imaging camera, perhaps resolution is the most critical. It provides the fineness of detail that a camera is capable of capturing, and with it, how accurately temperature gradients can be visualized. The higher the detector resolution, such as 640×480 pixels or higher, the more a user will be able to identify small targets or subtle temperature differences from farther away.

On the other hand, a low-resolution infrared camera blurs fine details, making it difficult to distinguish between close temperature zones or to pinpoint minor hot spots. This is especially important in various applications, such as PCB inspection, microelectronic analysis, and even medical diagnostics.

High-resolution imaging also means more data per frame, which further enables more accurate temperature measurement, smoother image processing, and better reporting vital to industries reliant on detailed analytics and compliance documentation.

Key Specifications That Make the Difference

When choosing a high-resolution infrared thermal camera imaging system, performance quality and usability depend on key specifications:

1. Detector Resolution: As the core of the camera, higher resolution detectors will collect more thermal data to produce greater clarity and more accurate measurements. Professional-grade cameras range from 640×480 to 1280×1024 pixels.

2. NETD: The NETD (noise equivalent temperature difference) refers to the minimum temperature difference that can be detected by the camera and is usually expressed in millikelvins (mK). For example, a Guide Sensmart NETD ≤30 mK is a high sensitivity level with high contrast between temperature areas.

3. Frame rate: High frame rates allow imaging to be smooth at 50-60 Hz, which is beneficial when tracking moving targets or dynamic thermal processes. An example is the use of drones in inspections, R&D experiments, or high-speed manufacturing lines.

4. Spectral range: Most thermographic cameras in infrared will operate in long-wave infrared (8-14 µm); however, on occasion, for specialty applications of higher temperature measurement or transmission through glass/smoke/mid-wave infrared (3-5 µm).

5. Temperature Range: The operational range for which a system is rated is generally -40°C to 2000°C, depending on the application of an industrial system.

6. Lens Choices and Focus: Interchangeable lenses with automatic focus help flexibility for different working distances (close-ups or large area scans).

7. Connectivity and Software: Modern high resolution thermal cameras have more capability for connection to analysis software, cloud processing, and AI-based defect detection processes for additional intelligence in diagnostics and reporting.

Uses of High Resolution Infrared Thermal Camera Imaging

High resolution infrared thermal camera imaging is used in a variety of applications, for example:

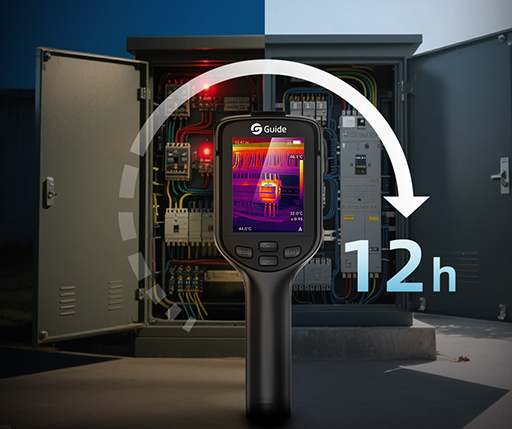

Electrical and Mechanical Maintenance: Identify problems like loose connections, overheating motors, and circuit overloads before they fail.

Building Inspection: Detect moisture intrusion, insulation deficiencies, and HVAC performance issues without cutting holes in any walls or ceilings.

Research and Development: Observe thermal performance in prototypes, semiconductors, and materials.

Public Safety/Defense: Provides night vision capabilities, surveilling from the air or ground, and performing search or rescue in low visibility conditions.

Medical-Veterinary Diagnostics: Detect thermal imbalances or anomalies in either human or animal physiology and perform contactless evaluations.

Selecting the Proper Infrared Camera for Thermal Imaging

When considering the purchase of an infrared camera for thermal imaging, performance and practicality should be balanced. High-performance cameras deliver the best performance in resolution and sensitivity, but the right camera depends on the application, price, and level of detail needed. For example, the Guide Sensmart's Hammer 2 Series provides solid performance, intuitive operation, and information through analytics that apply to the professional user working in industrial, construction, or research use.

When users invest in a high-resolution thermal imaging camera, they are investing in accuracy of diagnosis, reliable results, and long-term investment value to the individual's needs. Sensor technology continues to evolve, cameras are getting smaller, smarter, and more connected, which is facilitating thermal imaging's use across industries of all sizes.

Conclusion

The high-resolution infrared thermal camera market continues to change, offering unprecedented accuracy and flexibility in the thermal inspection and analysis market. Whether used in predictive maintenance, research, or safety monitoring, it is vital to know important specifications about resolution, sensitivity, and frame rate; these are the specifications that lead to optimal performance. If the correct infrared camera is selected to capture thermal images, a professional will see what others cannot- invisible heat patterns will be turned into actionable intelligence.

.svg)

.svg)