In the field of modern inspection and maintenance, handheld thermal imagers have become an essential tool, providing unprecedented portability and accuracy for on-site testing. From inspecting for hidden flaws in industrial equipment to finding energy loss in buildings, to inspecting for electrical system integrity, the miniature devices have transformed the manner in which on-site professionals work. This paper shall explore in detail the properties, functioning and extensive applications of handheld thermal imagers, highlighting their importance in many industries.

Compact Design: Redefining Portability

One of the best features of portable thermal imagers is that they are small and light. With a weight of around 500 grams, the tool is light enough to hold in one's hand and can be taken to any of a thousand work locations, allowing the technician to access difficult-to-reach areas with ease. Unlike bulky traditional inspection equipment, hand-held thermal cameras do not require installation and debugging time and can be brought into operation immediately. From ascending a ladder to investigate the HVAC unit on the roof to moving back and forth within narrow industrial pipeline systems, their portability greatly improves field inspection efficiency, allowing practitioners to get more inspection done in the same time.

Precision Technology: Revealing Hidden Facts

Handheld thermal imagers take advantage of the process of capturing infrared radiation emitted by objects. All objects with temperatures above absolute zero will radiate heat, and the thermal imagers convert the infrared signals to detailed images, with the colors distinguishing different temperatures. High-end models carry high-resolution sensors capable of detecting temperature differences as low as 0.01°C. Its precision allows technicians to detect eye-unseen problems, such as hot electrical contacts, insulation defects in the wall, or mechanical bearing wear. Providing precise temperature measurements and thermal images, portable thermal imagers provide invaluable evidence for diagnosing problems and formulating effective solutions.

Diverse Applications Across Industries

Industrial Maintenance

In industry, handheld thermal image cameras are employed for preventive maintenance. Technicians scan motors, generators, and conveyors at specified time intervals and detect incipient overheating, which may indicate impending mechanical failure. For example, minor increase in motor bearing temperature may indicate a lubrication problem or misalignment of components. By detecting these problems up-front, maintenance personnel can plan repairs in advance and prevent downtime and the expensive potential for equipment breakdown.

Building Energy Audits

Handheld thermal imaging cameras are used to conduct energy audit in building and energy industries. Thermal imaging cameras can quickly identify areas of heat loss in a building, such as gaps in insulation, faulty windows, or inefficient heating systems. With thermographic images of walls, roofs, and floors, energy auditors can identify areas of energy loss and provide detailed recommendations for improvement. This not only enables building owners to reduce energy consumption and electricity bills, but also aids environmental sustainability through the reduction of carbon emissions.

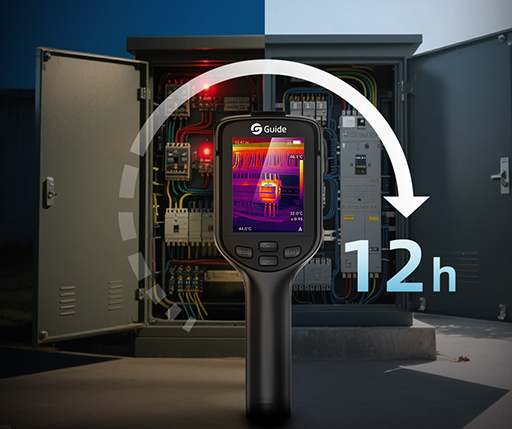

Electrical System Checks

Electrical systems are a significant area of application for where handheld thermal imaging cameras find use. They are able to detect hot spots on switchboards, circuit breakers, and power lines that may suggest loose connections, overloaded circuits, or equipment failure. Detection of such issues at an early stage is necessary in the prevention of electrical fires and safeguarding people and facilities against damage. Handheld thermal imaging cameras enable electricians to check systems quickly without de-energizing or dismantling equipment.

Apart from the applications in construction and industry, the handheld thermal camera is also a critical instrument in rescue operations in case of disaster and inspections in public safety. In disaster sites, such as earthquake disaster areas or fire-stricken buildings, visibility is generally very low due to ruins, thick smoke or dark environments. Handheld thermal cameras can penetrate such obstacles, allowing rescuers to detect body heat. The portability of the equipment allows rescue teams to quickly search large areas, dramatically increasing the success rate in rescue.

For situations of public safety, such as airports, railroad terminals, or large event venues, handheld thermal imagers are utilized for touchless temperature screening. This application is particularly important for public health cases because it can identify individuals with abnormal body temperatures without having to touch them potentially an early sign of disease. With rapid and accurate temperature measurement, these devices aid in early detection and prevention, as well as in the protection of public health and safety.

Conclusion

Handheld thermal imagers have revolutionized field inspection with their perfect combination of portability and accuracy. They can be used with versatility in varying working environments because of their compact size, and their advanced thermal imaging method provides visibility to hidden problems. As industries increasingly prioritize efficiency, safety, and sustainability, demand for multi-purpose devices such as handheld thermal imagers will continue to grow. From the maintenance of industrial equipment and optimization of building energy to electrical safety and rescue in emergencies and public health protection, handheld thermal imagers are becoming more and more the tool of choice among professionals in an extremely broad variety of industries. If you have any interest in handheld thermal imagers, please contact Guide Sensmart.

.svg)

.svg)