When the target temperature exceeds 2000℃, the measuring size is only as a fingernail, or it's tens of meters away… have these extreme temperature measurement scenarios ever left you at a loss for where to begin your inspection work?

The value of infrared thermal imagers lies in overcoming these temperature measurement dilemmas. They enable non-contact, visualized, and highly efficient temperature detection, becoming an indispensable "temperature eye" in industrial inspection and scientific research.

See how Guide Sensmart helps customers achieve "clear vision and accurate measurement" in five typical extreme scenarios!

Condition 1: Ultra- high temperature

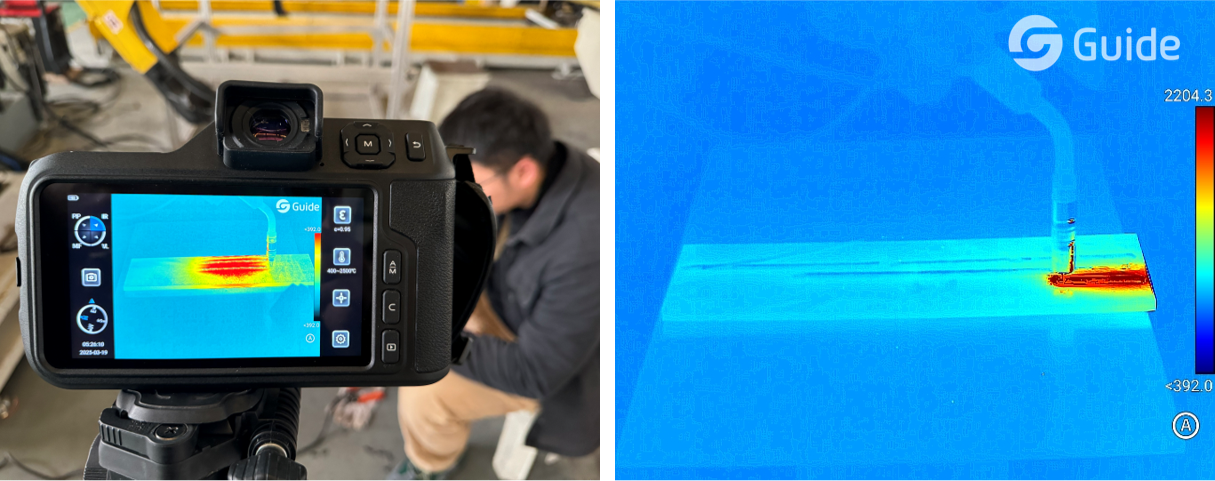

A university laboratory collaborated with a robotics company to tackle welding technology challenges. The temperature of the weld pool exceeds 2000℃, and traditional methods cannot observe its dynamic thermal field, making it difficult to predict the welding quality (such as porosity and cracks). Process optimization relies on trial and error, which is costly.

Solution

Utilizing Guide Sensmart PT series infrared thermal imagers, with the addition of a high-temperature lens to extend the temperature measurement upper limit to 2500℃. Non-contact, real-time temperature measurement across the entire area transforms the temperature field into a clear and visible thermal distribution map.

Core value

Allows for intuitive observation of the molten pool state and rapid identification of quality anomalies; accurately records temperature distribution and data under different process parameters, achieving "visualization" of the welding process and "datafication" of parameter optimization, improving the reliability of results transformation, and ensuring consistency between laboratory and mass production processes.

Condition 2: The measurement target is extremely small

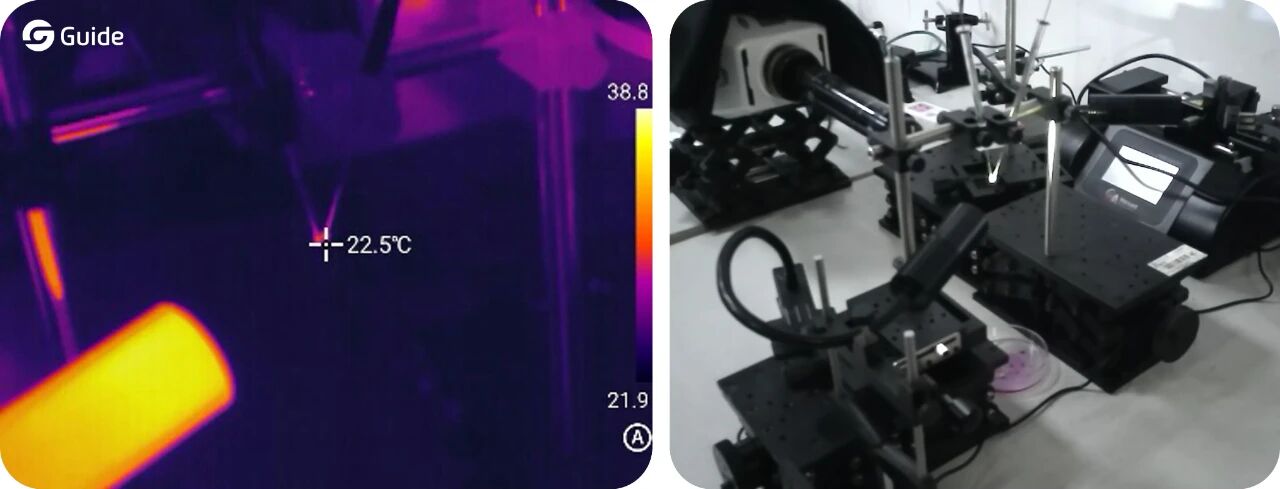

A manufacturer of micro-projector optical engines needed to assess the impact of chip heat on the stability of projected image color and brightness during its research and development. The chip and heat-generating area are extremely small, making it difficult to capture the global heat distribution using traditional methods, and also requiring adherence to avoid interfering with chip operation.

Solution

A H6S series infrared thermal imager with a dedicated macro lens was used to construct a simulated working environment of 80~150℃ for testing. At a close distance of 100mm, the spatial resolution reached 50μm, fully revealing the chip's thermal distribution.

Core value

Visualizing the heating patterns and temperature field distribution of chips, obtaining correlation data between "temperature and imaging", breaking through the bottleneck of temperature measurement of micro-targets, accelerating R&D iteration, and establishing data-driven quality control standards.

Condition 3: Small temperature difference

A university conducted research on fluid mixing phenomena, using glycerol solution as the research object. The temperature change at the moment of fusion is very small and the process is extremely short. Traditional temperature measurement methods cannot capture this tiny temperature difference, resulting in a lack of accurate data support for the research.

Solution

The Guide Sensmart H series infrared thermal imager is used , with a 640×480 infrared resolution and high thermal sensitivity. It can capture temperature changes as small as 0.04℃, accurately capturing subtle temperature differences in the droplet experiment and providing reliable temperature data for research experiments.

Core value

Completely record small temperature fluctuations and dynamic data, ensure the authenticity of experimental data, provide reliable evidence for the study of fluid mixing mechanisms, and help advance scientific research projects.

Condition 4: High temperatures make it difficult to approach the target safely

A leading new materials company provides maintenance services to chemical customers . The "internal damage" such as corrosion and breakage of the lining of reactors and pipelines is not visible to the naked eye. It is difficult for personnel to approach high-temperature and high-risk areas. Traditional inspections require shutdown, and maintenance reports lack quantitative data support.

Solution

Purchase Guide Sensmart H series flagship infrared thermal imager. Through non-contact, wide-area inspection, areas with potential thermal hazards are automatically highlighted. Combined with panoramic stitching function, it can meet global inspection needs.

Core value

Non-stop inspection to improve safety and coverage; Visual and quantitative presentation of damage, intelligent generation of professional reports, and promotion of maintenance from passive inspection to proactive prevention.

Condition 5: Long-distance measurement

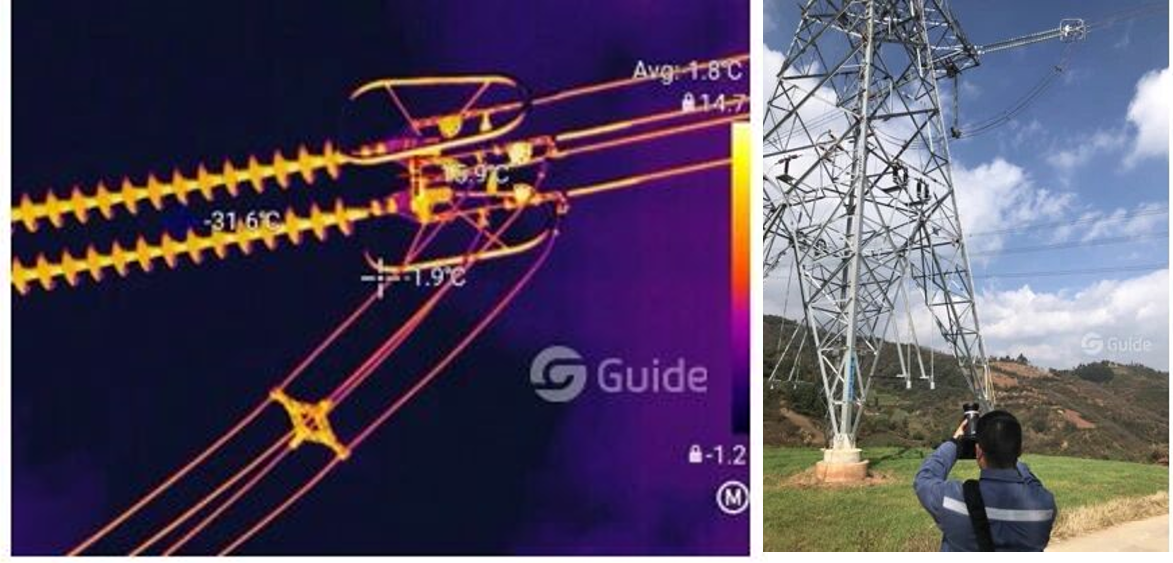

A certain operation and maintenance station of a Power Grid is responsible for the operation and maintenance of more than 2,000 kilometers of transmission lines. The lines are distributed across mountains and have high towers, making traditional manual inspections inefficient and exacerbating the difficulty in severe weather.

Solution

It adopts the Guide Sensmart Infrared Thermal Imager equipped with a telephoto lens to achieve accurate temperature measurement at a long distance. It does not rely on ambient light and supports visual inspection at night and in severe weather. The intelligent ledger and cloud service functions can generate reports instantly for efficient operation and maintenance.

Core Values

Patrol personnel can locate potential thermal hazards in high-altitude fittings simply by standing under the tower, significantly improving inspection efficiency, reducing labor costs, and ensuring stable line operation under high loads.

.svg)

.svg)