Heat loss occurs in buildings, industries, and mechanical systems. In most instances, people only notice the problem when energy bills increase or comfort levels decrease. The main difficulty is that heat loss is often invisible to the naked eye.

Infrared thermal imaging cameras solve this problem by converting temperature differences into clear visual information. This makes them an efficient tool for identifying the location and cause of heat loss.

Why is Heat Loss Difficult to Detect with the Naked Eye?

Most heat loss occurs behind the walls, under the ceilings, and even inside the structure of the building. From the outside, even significant heat loss often leaves the surface looking perfectly normal.

Traditional inspection methods have limitations:

Visual inspection cannot detect temperature differences.

Physical inspection requires disassembling the equipment.

Often, guesswork is used instead of precise measurements.

Therefore, heat loss is frequently underestimated or misdiagnosed.

How Does Thermal Imaging Technology Reveal Hidden Temperature Differences?

Thermal imaging cameras can detect infrared radiation emitted by objects. This radiation changes with temperature, even if the objects appear identical in color or texture.

These cameras convert these temperature differences into color images, allowing users to:

Instantly view hot and cold areas

Identify uneven heat distribution

Detect abnormal temperature patterns

Thus, the loss of heat can easily be detected without altering any part of the structure being inspected.

Identifying Heat Loss in Building Envelopes

Building envelopes include walls, roofs, windows, and doors. These are common areas where heat is easily lost.

Thermal imaging cameras can help with:

Revealing gaps in wall insulation

Showing air leaks around windows and doors

Highlighting areas of poor insulation in the roof

Inspectors can accurately pinpoint problems without guesswork.

Detecting Insulation Defects and Thermal Bridges

Insulation defects are often uneven. Part of a wall may be well-insulated, while another part rapidly loses heat.

Thermal imaging technology is highly effective for:

Identifying missing or compressed insulation materials

Locating thermal bridges caused by structural components

Comparing insulated and uninsulated areas

This level of detail cannot be obtained through traditional tools.

Understanding Energy Loss Caused by Air Leaks

Air leaks are a major cause of energy loss. Warm air escapes through gaps, while cold air enters the building, increasing heating demands.

Thermal imaging technology can:

Visualize cold air infiltration paths

Show temperature changes caused by airflow

Help identify areas where air sealing is needed

This allows for targeted improvements rather than extensive and costly renovations.

Improving Energy Efficiency Assessments

Energy audits aim to identify areas of energy inefficiency and propose improvements. Thermal imaging technology can make these assessments clearer and more effective.

By using infrared thermal imaging cameras, auditors can:

Prioritize the most crucial heat-loss areas.

Track effectiveness of repairs and improvements

Clear images make reports easier to understand and implement.

Supports Preventative Maintenance and Planning

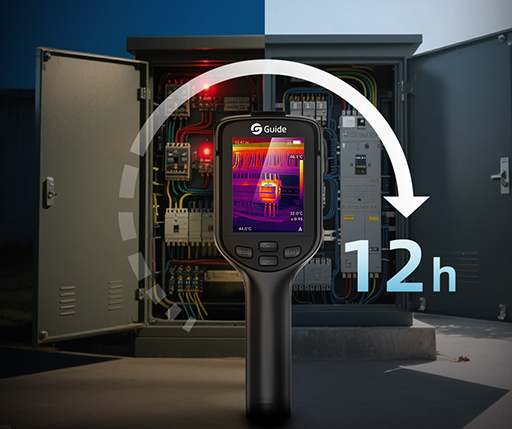

Heat loss isn't limited to buildings. Pipes, ducts, and industrial systems also lose energy over time.

Thermal imaging technology helps to:

Monitor insulation performance

Detect gradual performance degradation

Detect problems before energy loss occurs on a large scale

This helps in developing long-term energy management strategies.

Compared to Traditional Methods, Thermal Imaging Saves Time

Traditional heat dissipation testing methods may involve invasive testing, repeated measurements, or trial-and-error repairs.

Thermal imaging tools offer the following advantages:

Fast scanning of large areas

Instant results

Minimizing disruption

This efficiency reduces testing time and lowers labor costs.

Enhancing Communication and Decision-Making Capabilities

A major advantage of thermal imaging technology is that its results are easy to understand and communicate.

Thermal imaging tools:

Provide clear visual evidence of heat loss

Reduce disagreements among stakeholders

Enable informed decision-making

This is particularly useful in renovation or energy upgrade projects.

Practical Applications in Different Scenarios

Thermal imaging cameras are effective in a variety of environments:

Residential buildings

Commercial facilities

Industrial plants

HVAC systems and pipes

In all of these application scenarios, the goal is the same: to identify areas of energy waste and take appropriate action.

Conclusion

Thermal imaging cameras are an effective tool for identifying heat loss because they can reveal temperature differences that are invisible to the naked eye. They can reduce guesswork, speed up detection, and provide clear evidence for decision-making.

By precisely showing where heat is being lost, thermal imaging cameras help facilitate targeted improvements, increase energy efficiency, and achieve long-term cost savings. As energy efficiency becomes increasingly important, the value of thermal imaging technology as a practical and reliable inspection tool is becoming more and more evident. Guide Sensmart is a manufacturer of thermal imaging cameras and looks forward to collaborating with you.

.svg)

.svg)