Unplanned downtime is one of the biggest challenges facing industrial operations. Whether it's a production line, power system, or processing facility, unexpected equipment failures can lead to production losses, increased maintenance costs, and safety risks.

Industrial thermal cameras provide a practical and effective way to detect problems early, before they lead to downtime. By visualizing temperature changes, these tools can help maintenance teams detect hidden issues that are often missed by traditional inspection methods.

Why do Equipment Failures Often Begin with Small, Imperceptible Problems?

Most equipment failures don't happen suddenly, but rather develop gradually due to factors such as friction, resistance, poor insulation, or mechanical wear.

Common early warning signs include:

Minor overheating

Uneven temperature distribution

Slow increase in temperature over time

These changes are often difficult to detect with the naked eye, especially when the equipment is operating normally.

How Industrial Thermal Imagers Work in Real-World Environments

Industrial thermal imagers detect infrared radiation emitted by objects and convert it into temperature-based images.

This allows operators to:

Contactless monitoring of equipment

Perform inspections while the system is in operation

Immediately identify abnormal heat patterns

Unlike traditional tools, thermal imagers allow for inspection without requiring system shutdown or disassembly.

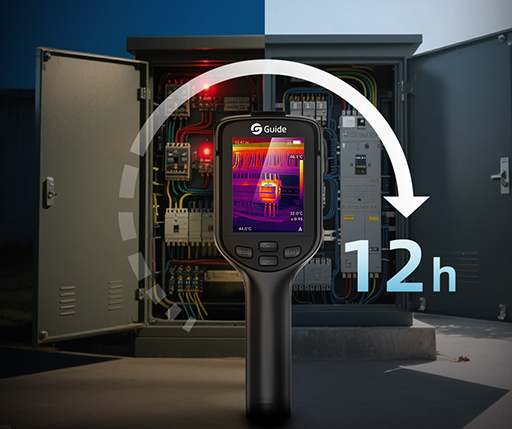

Detecting Electrical Problems Before Failure Occurs

Electrical faults are one of the main causes of industrial downtime. Loose connections, unbalanced loads, and aging components often generate excessive heat.

Industrial thermal imagers assist in:

Identifying overheating cables and terminals

Detecting load imbalances in distribution panels

Finding faulty circuit breakers and transformers

If problems can be identified earlier, it allows for maintenance before any downtime occurs, rather than performing emergency repairs.

Identifying Mechanical Wear and Friction Problems

Mechanical components such as bearings, motors, and belts generate heat during the wear process.

Thermal imaging technology helps to:

Detect misalignment and excessive friction

Monitor abnormal temperature increases in rotating parts

This reduces reliance on single detection methods such as sound or vibration, and provides visual confirmation of potential problems.

Monitoring Motors, Pumps, and Rotating Equipment

Motors and pumps are critical pieces of equipment in industrial operations and are common sources of failure.

Thermal imaging cameras can help teams:

Compare temperatures between similar equipment

Identify overheating caused by overloading

Detect cooling system failures

Thus, by identifying temperature differences as early as possible, teams can plan maintenance proactively without disrupting production.

Supporting Predictive Maintenance Programs

Predictive maintenance focuses on preventing failures rather than reacting to them. Thermal imaging technology is perfectly suited to this approach.

By conducting regular thermal imaging inspections, teams can:

Track temperature trends over time

Identify gradual performance degradation

Schedule maintenance based on actual conditions

This data-driven approach reduces unnecessary maintenance and unplanned downtime.

Enhancing Safety and Reducing Downtime Risks

Industrial environments often involve high voltage, high temperatures, and moving machinery.

Thermal cameras can improve safety in the following ways:

Allowing inspections from a safe distance

Reducing the need for access into live electrical panels

Identifying dangerous hot spots before contact

Safer inspections also mean fewer failures and faster decision-making.

Reducing Maintenance Costs and Emergency Repair Expenses

Emergency repairs are both time-consuming and expensive. Thermal imaging technology helps shift maintenance from a reactive to a planned approach.

The advantages are as follows:

Reduced unexpected breakdowns

Reduced overtime and repair costs

Better planning of spare parts inventory

In the long run, these savings often outweigh the cost of the thermal imager itself.

Making Inspection Results Easy to Understand and Share

One of the major advantages of thermal imaging technology is its clarity and intuitiveness. Temperature differences are presented in image form, making problems easier to explain.

Thermal images help to:

Communicate problems to management

Provide justification of maintenance actions

Document existing conditions for future comparison

Clear images reduce misunderstandings and expedite the approval process.

Common Industrial Applications of Thermal Imaging Cameras

Industrial thermal cameras are widely used in:

Manufacturing plants

Power generation and distribution

Oil and gas facilities

Production of chemicals

Heavy equipment maintenance

In all these applications, the goal is the same: to detect problems early and avoid downtime.

Conclusion

Industrial thermal cameras are an essential tool for effectively detecting faults and preventing downtime. They can reveal temperature changes that indicate early signs of failure, allowing maintenance teams to take action before a fault causes operational disruption.

Companies should not passively react to equipment failures but instead shift to planned and predictive maintenance. This can improve reliability, enhance safety, and reduce overall operating costs. In modern industrial environments, thermal imaging technology is no longer an optional extra but a practical solution for ensuring smooth system operation.

.svg)

.svg)