Accurate and prompt leak detection is necessary in multiple industries and even in domestic environments. From hidden water leaks in pipelines to air leaks in structures, such apparently tiny problems can lead to catastrophic destruction if not detected in time.Thermal imaging cameras were developed with such needs, providing an efficient solution for accurate leak detection.

Thermal Imaging Technology Basics

Thermal imaging cameras work by detecting infrared radiation. All objects above absolute zero emit heat, and the camera picks up this infrared energy and displays it as an image. Different temperatures are differentiated by color or hue, forming a heat map. When there is a leak, a leak will typically read a temperature difference in the surrounding material. For example, a leak in a water-carrying pipe will cause the surrounding area of the leak to be warmer or colder than usual, depending on ambient conditions and on the temperature of water in the pipe. The temperature difference will appear quite distinctly in the thermal image, and the user can merely pinpoint the location of the leak.

Advantages of Thermal Imaging Cameras in Leak Detection

Unparalleled Accuracy

One of the major advantages of thermal imagers is that their accuracy. Traditional leak detection techniques using visual inspection or moisture metering will rely on surface - level clues and can miss the precise location of leaks behind walls, floors or other obstructions. Thermal imagers detect temperature differences on the surfaces of objects, enabling the tracking of leaks and the precise indication of their positions. This precision saves time, not to mention decreases repair expense since technicians can detect which parts need repairing without additional dismantling or demolition of support mechanisms.

Effective and Time-Saving

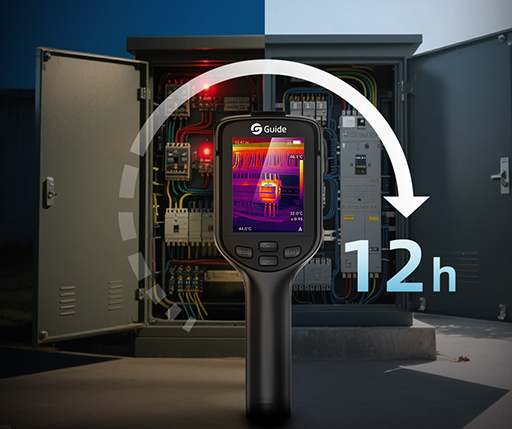

Thermal imaging cameras can cover large areas in a flash. If the job is to find air leaks inside a building or water leaks along a huge chunk of pipe, the camera scans only minutes. It is this ability to scan quickly that renders it revolutionary to large industrial operations or even in crisis situations, where immediate detection is necessary. Unlike traditional methods that take hours or even days to search for leaks, thermal imaging cameras can provide results instantly to enable quick action against additional damage.

Non-Intrusive Inspection

Another important advantage is that thermal imaging is a non-intrusive inspection method. No physical contact with the subject under test and does not cause any damage to the structure. For example, in the testing of leaks in old buildings or delicate industrial plants, thermal imaging camera use can offer effective leak detection while ensuring the structure or equipment integrity. This lack of intrusiveness also translates into fewer interruptions in normal operations, hence the favorite choice for the majority of companies and proprietors.

Applications of Thermal Imaging Cameras in Leak Detection

Construction and Building Industry

In the building and construction industry, thermal imaging cameras are used in the detection of air leaks in buildings. Air leaks reduce the efficiency of a building, thus increased heating and cooling cost. Contractors use thermal imagers to view air leaking from cracks and gaps so that they can caulk them to make the building better insulated. Thermal imaging also assists one in finding roof leaks, wall, and ducts so that one may not incur losses through water invasion or mold accumulation.

Industrial

Thermal imaging cameras are employed on factory floors to detect leaks in tanks, valves, and pipes. Leaks cause loss of valuable resources, pollution of the environment, and even pose safety hazards. Through thermal imaging technology, the leaks can be identified early enough such that necessary steps can be taken before they worsen. For instance, thermal cameras can be utilized in a chemical plant to spot minute leaks of dangerous chemicals through pipelines so as to avoid any possible leakage accidents and preserve the safety of employees and the environment.

Home Applications

Even at the residence, thermal imaging cameras are used significantly to detect leaks. Individuals apply them in a bid to find hidden leaks in pipes which can destroy walls, floors, or foundations. By identifying the leaks early, homeowners do not spend a significant amount of cash on repairs at a later point in time.

Conclusion

In brief, thermal imaging cameras have been the best in leak detection. Their high technology, coupled with many advantages such as high accuracy, time-saving effectiveness and non-invasiveness, necessitate them to be an essential tool in many applications. From the construction and building industry, industrial plants or household application, thermal imaging cameras provide an effective and safe method of leak detection, avoiding damage, saving resources and ensuring safety.Guide Sensmart is a thermal imaging camera manufacturer with a few years of export history. Please feel free to consult.

.svg)

.svg)